James Pikul’s “Metallic Wood” Featured in The Inquirer

James Pikul, assistant professor in the Department of Mechanical Engineering and Applied Mechanics at Penn Engineering, published a study in January detailing a new material his lab created. Their nanostructured material has the strength of titanium while being four to five times less dense, earning it the nickname “metallic wood.”

Pikul’s metallic wood quickly grabbed the attention of the design world for its functional and aesthetic potential. More recently, The Inquirer has featured Pikul’s creation, focusing on where the idea originated, how exactly the material is formed, and the possible applications.

Tom Avril of The Inquirer walks through the ingenious process used to create metallic wood:

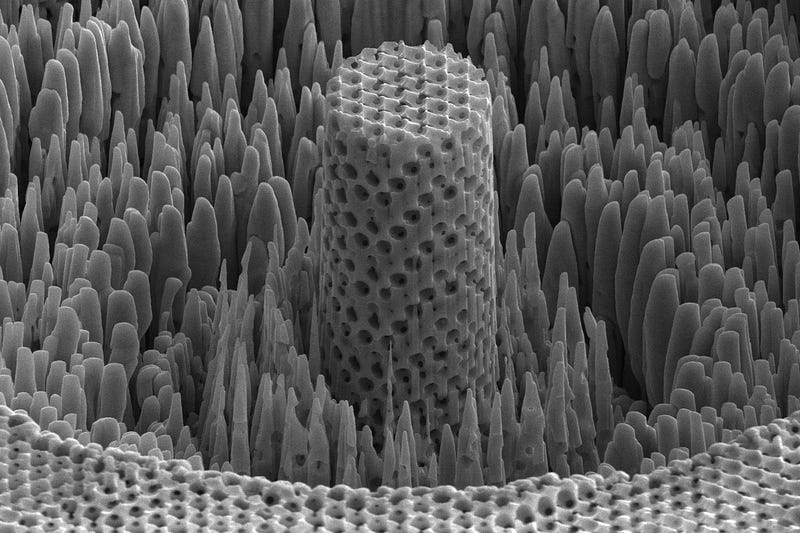

“Start with billions of tiny plastic spheres suspended in a small vial of water. Insert a substrate — a strip of glasslike material that conducts electricity — and heat up the water. As the water evaporates, the spheres settle on the strip in an orderly pattern, stacking themselves almost like a pyramid of oranges in a grocery-store display.”

Continue reading about how metallic wood is made in the Inquirer.